UNICUT® Nozzles are precise and robust at the same time. Made of stainless steel, they are resistant against flying burrs and mechanical stress. The UNICUT® full cone nozzles are two-phase nozzles with a separate air and fluid flow. Due to the pressure-tight connection of nozzle and fluid line, air and fluid only come into direct contact when exiting the nozzle which enables a very precise and low-mist spray pattern. Another positive side effect of this type of connection is that fluid and spray air pressure can be controlled independently from one another.

UNICUT® 1/8“ Full Cone Nozzle

UNICUT® 7mm Full Cone Nozzle

UNICUT® M-Nozzle Head

- Nozzle: 3 x 1/8“

- Application: circular saws

- From diameters of Ø 800 mm

UNICUT® All-round Nozzle Head with 3 Nozzles

2 cooling nozzles

Lubrication nozzle

- For cooling and lubricating the saw blade

- Nozzle: 3 x 7 mm, 1 x lubrication, 2 x cooling

- Application: Underfloor saws, circular saws

- up to diameters of Ø 800 mm

UNICUT® 5-fold All-round Nozzle Head

Cooling nozzle

Cooling nozzle

3 lubrication nozzles

- For cooling and lubricating the saw blade

- Nozzle: 5 x 1/8“, 3 x lubrication, 2 x cooling

- Type of processing: Circular saw

Nozzle heads for circular saw applications supplied by UNICUT® can be used to lubricate and cool circular saws, whatever your application may be. UNICUT® always offers the right solution for your equipment. Particularly the UNICUT® all-round nozzles make sure that the saw blade is lubricated by the nozzle head, while at the same time a coolant can be sprayed onto the steel blade, which means that in applications with hard metal saw blades the nozzle is not removed to exchange the saw blade.

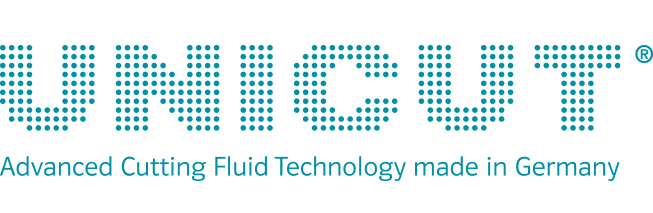

UNICUT® Stainless Steel U-shaped Nozzle Head

- Nozzle: 3 x 7 mm

- Type of processing: Band saw

- up to a saw blade height of 67 mm

UNICUT® U-shaped Nozzle Head

- Nozzle: 3 x 7 mm

- Type of processing: Band saw

- up to a saw blade height of 80 mm

Nozzle heads for band saws have been designed in such a way that saw blade heights from 34 – 90 mm can be covered. Due to the design with three nozzles fitted both the saw teeth as well as the back of the blade are lubricated.

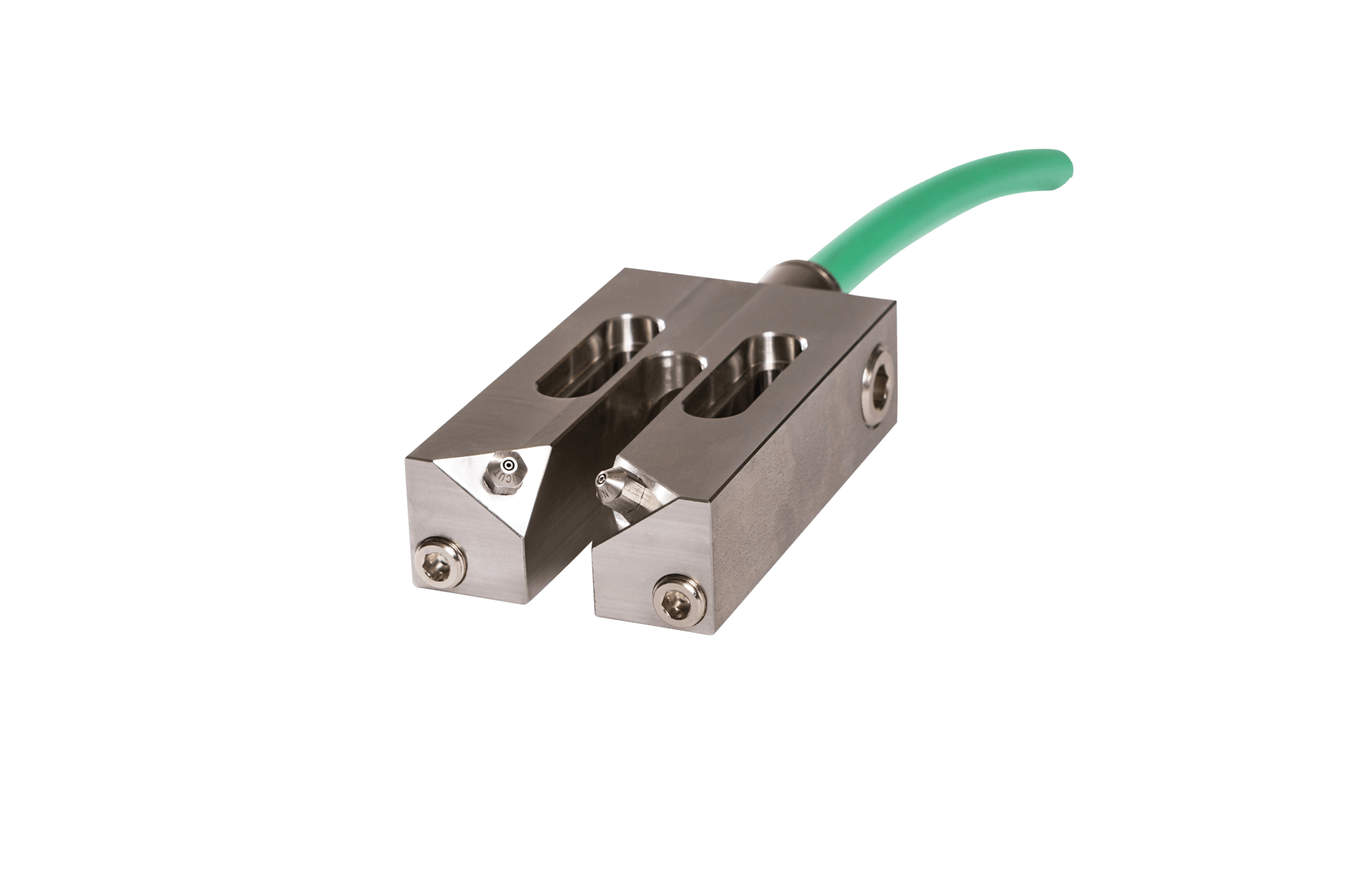

UNICUT® Extended Nozzle

with Stainless Steel Tube

Tube Ø 8 mm

Nozzle: 1 x 7 mm

Due to the modular design of the UNICUT® MMS systems custom solutions can be implemented easily and cost-effectively. Sucessfully accomplished projects include those in profile lubrication, profile cleaning, strip slitting and many more.

Zentrale Deutschland / Germany

UNICUT® Wahl GmbH

Feld-Vorstmann-Straße 14

56170 Bendorf/Germany

Fon: +49 26 22 42 66

Fax: +49 26 22 26 03

E-mail: info@unicut.de

www.unicut-wahl.de

Vertriebspartner / Trading partner – Europe

FAIRCUT cutting solutions

Sandforter Weg 7

D- 59379 Selm - Germany

Fon: +49 (0) 2592 973344-61

Fax: +49 (0) 2592 973344-66

Mobil: +49 (0) 17556 77 247

E-mail: bennewitz@faircut.eu

www.faircut.eu

Vertriebspartner / Trading partner – Asia / China

Chongqing DianDi business trade Ltd.

04-10F, Jiulongwann Jinyu Building,

Zhigang big street,

400050 Jiulongpon district, Chongqing

P.R.C

Fon: +86 (0) 23 6816 1035

Fax: +86 (0) 23 6816 1039

Mobil: +86 (0) 133 203 55 911

E-mail: 1321853996@qq.com

Vertriebspartner / Trading partner – Turkey

BCM Makina Kimya

İth. Ve İhr. San.Tic.Ltd.Şti.

Mahmut Yesari Sk.

No:10 34718

Koşuyolu / Kadıköy / İSTANBUL

Fon: +90 216 545 62 94

Fax: +90 216 545 86 94

Mobil: +90 532 275 80 66

E-mail: cenk@bcmkim.com